With the development of automobile drive motor to high performance, high efficiency and high power density, flat line motor has gradually become the object of new energy vehicle drive motor because of its high slot full rate, high heat dissipation efficiency and good NVH characteristics.

The application of flat wire motor in new energy vehicles starts from the Advanced Integrated Drive system (DOE) project led by the Department of Energy of the United States, in which the motor adopts three key technologies, one is five-phase winding, one is double V magnetic pole structure, and the other is flat wire motor.

At the end of the DOE project in 2011, the first Chevrolet model with flat-line motor was also released.

With the rapid development of new energy vehicles and the rapid improvement of product quality, consumers have higher and higher requirements for vehicle performance.

As flat-line motors have obvious advantages over round-line motors in terms of high efficiency, high power density, excellent NVH, high integration and low cost, more and more high-end models are equipped with flat-line motors. It is expected that the permeability of flat-line motors will be higher by 2025.

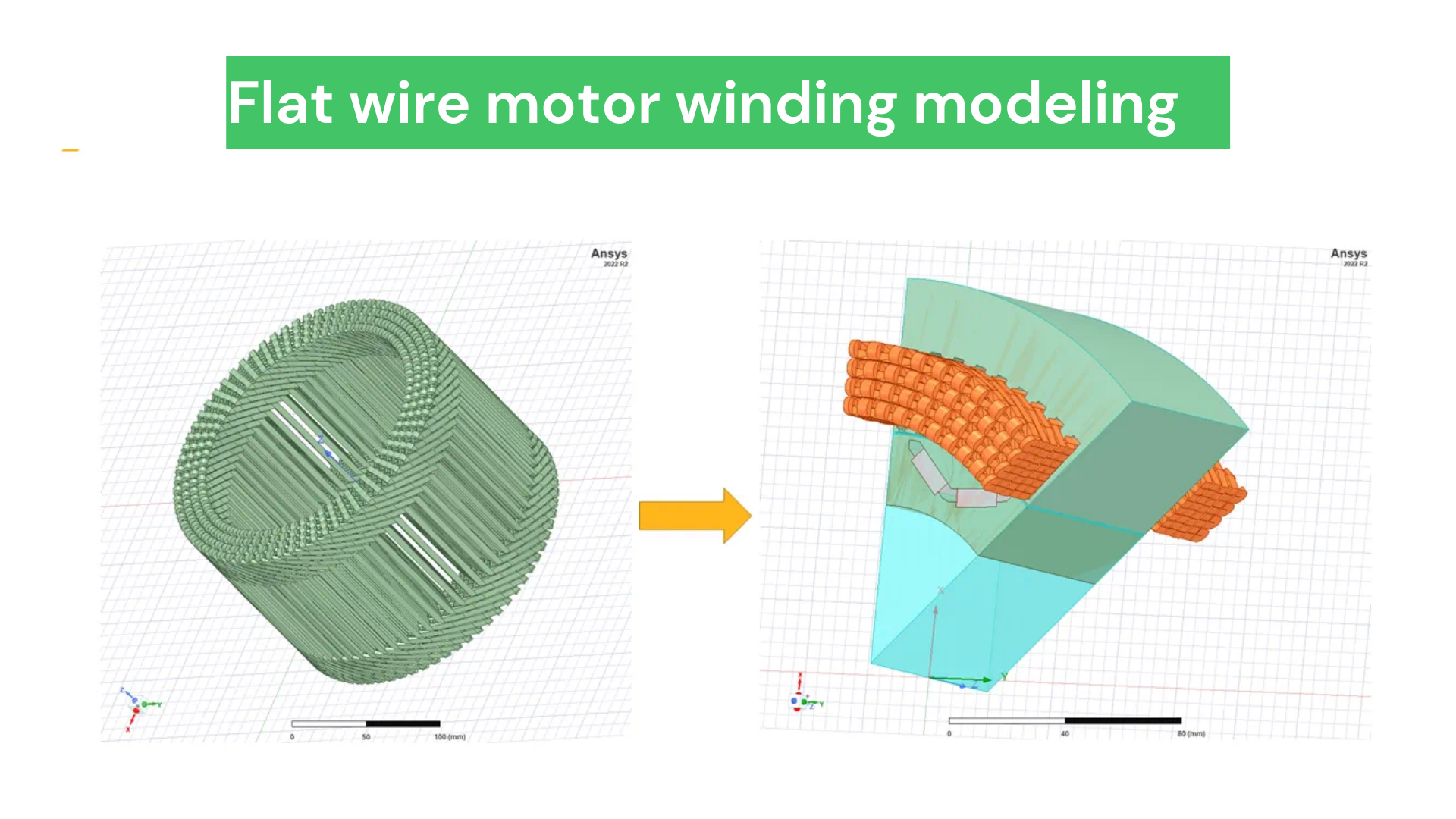

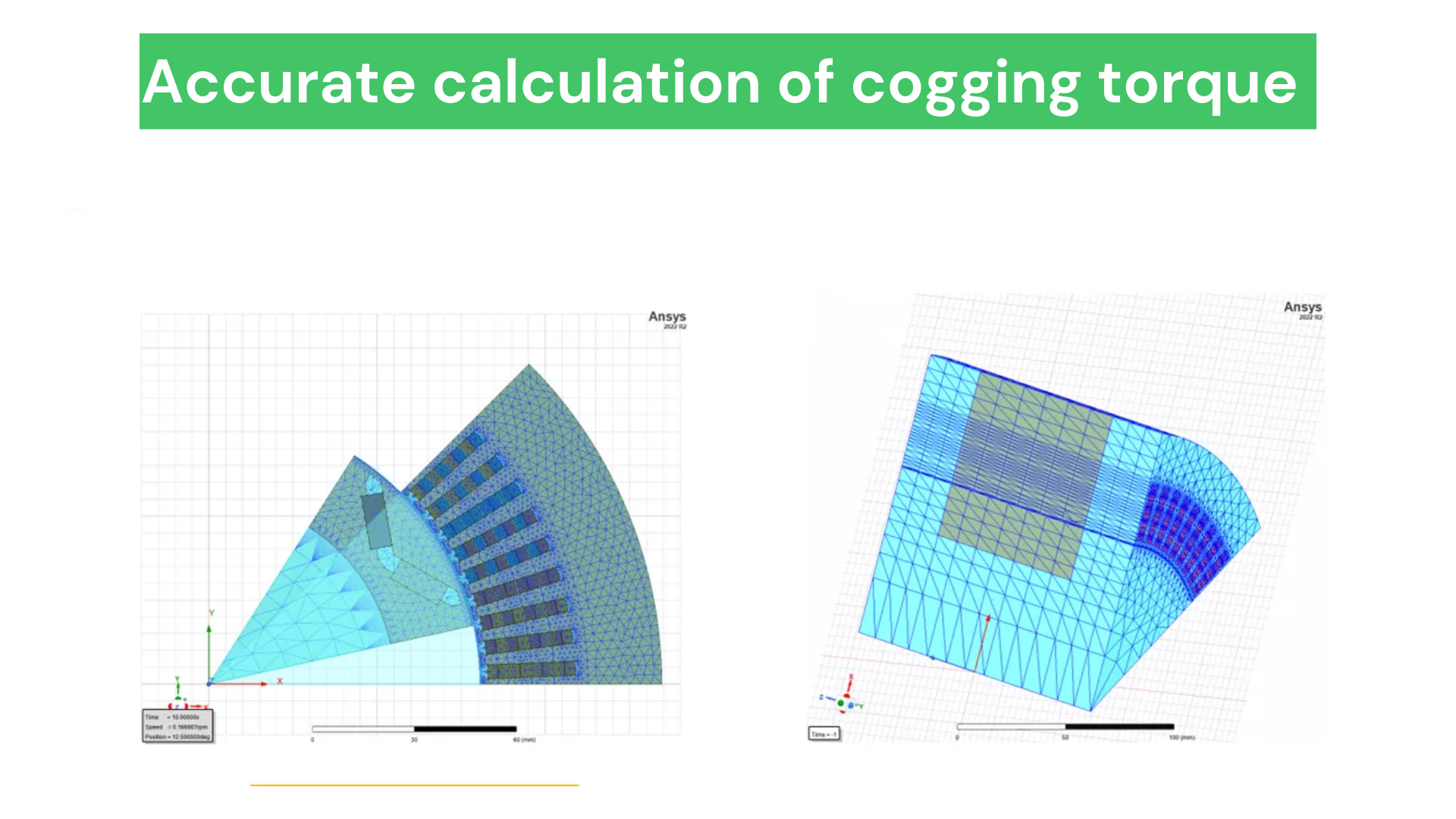

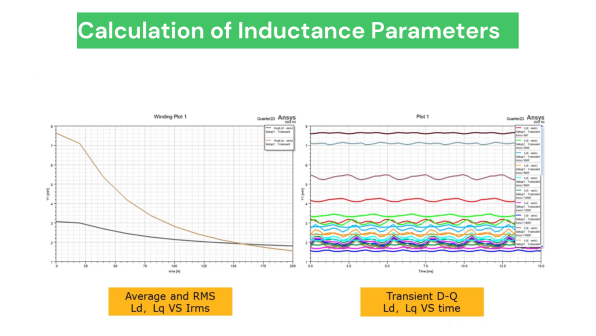

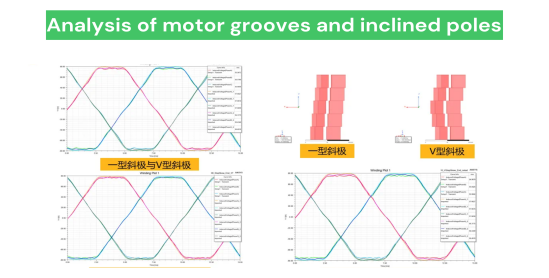

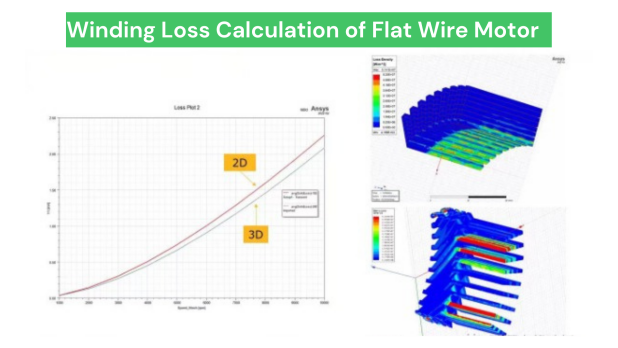

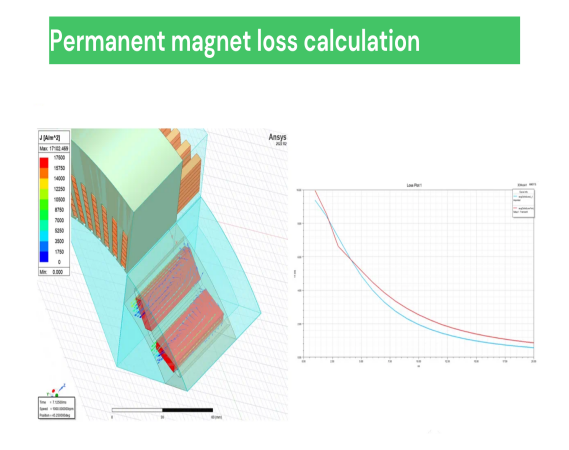

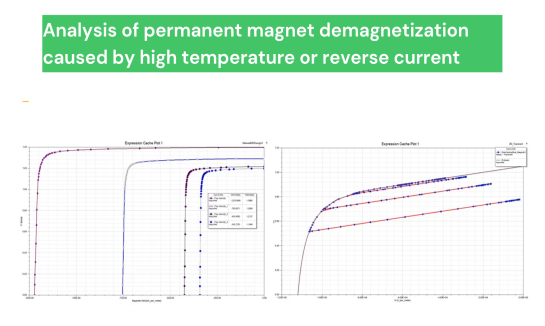

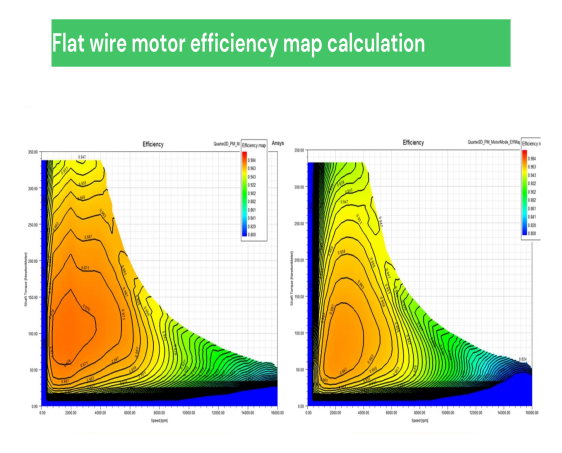

In the process of completing the design of flat wire motor for driving new energy vehicles, a large number of simulation calculations are usually needed to evaluate the performance of flat wire motor more accurately. In the process of design and simulation, we usually need to do the following work:

1.

2.

3.

4.

5.

6.

7.

8.

Tel:13682535324

Address:No. 129, Yuquan East Road, Yulu Community, Yutang Street, Guangming District, Shenzhen