With the continuous development of science and technology, brushless motors are more and more widely used and favored by the majority of friends, such as aircraft models, drones, scooters, electric cars, etc., including the popular series of power tools, network celebrity hair dryers, electric toothbrushes, new energy vehicles, etc., all equipped with brushless motors, compared with brushless motors, brushless motors have more advantages, so we will not introduce them here.

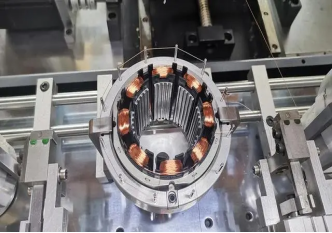

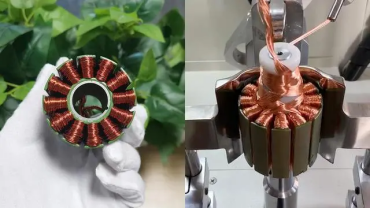

Brushless motor has two key components, that is, the stator rotor. When it comes to the stator, it is necessary to talk about the coil, and the winding of the coil is a more important process. If it is not wound well, the broken and broken wires will affect the performance and quality of the brushless motor. Therefore, the winding quality must be well controlled in motor production.

In the past, manual or semi-automatic equipment was commonly used to wind the wire, but the efficiency was relatively low. If the number of turns is more, the workers are always easy to remember wrong. Although one lap will not affect too much, it is certainly more reasonable to design the number of laps.

With the development of science and technology, more advanced automatic equipment and automatic winding machine are adopted, which can realize automatic winding, automatic wire arrangement, automatic transposition and automatic clipping, and the quality can be better controlled.

The working principle and winding mode of automatic winding machine:

1.

Flying fork external winding machine, this is a more common way of external winding, for the slot outward stator products, brush motor can also use this winding mode, relatively economical.

The working principle is to use the high-speed rotation of the flying fork to drive the wire nozzle to rotate, and the wire nozzle follows the movement with enamelled wire. Under the interaction of die, mold and guard plate, the line is stuck into the stator slot, and the precision wire arrangement can be realized. The premise is that the machine configuration is good enough. Mold, wiring device, and controller precision.

2.针式内绕机,这是比较常见的内绕线方式,针对槽口向内的定子产品,可分为上勾线绕线和下勾线绕线方式,这主要取决于出线要求。工作原理就是伺服带动针杆高速上下运动,针杆上有线嘴,线嘴带着线一起运动,在上下运行的同时前后移动,同时模具不停的左右移动,然后漆包线就绕进定子槽口里,可实现精密排线。密度好

Tel:13682535324

Address:No. 129, Yuquan East Road, Yulu Community, Yutang Street, Guangming District, Shenzhen